Introducing The Aurum®

Innovative. Secure. Beautiful. Timeless.

Introducing the Aurum®, the smallest verifiable unit of gold for investment available on the market today. Lightweight and easily storable, Aurum are manufactured using cutting edge, proprietary technology for a product that modernizes precious metal investment. Individual Aurum are available in practical quantities with a wide range of values and represent a competitive alternative to traditional currencies. Valaurum, Inc. has developed this completely unique process and currently has U.S. and international patents pending in Europe, China, Taiwan, Hong Kong, Singapore, Iceland, India, Australia, and Canada.

Security Features

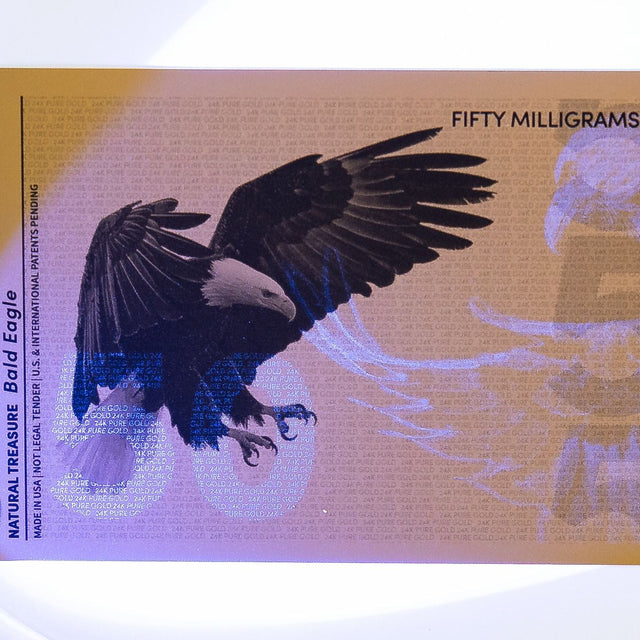

UV Security Layer

Our latest security innovation is designed to provide additional protection for your gold investments. We’re thrilled to include UV-fluorescent components as part of each bill in our latest series, the Natural Treasure collection. In addition to its function as a security feature, each Aurum’s UV security layer uses a relief of art elements from the opposite side of the bill, enhancing the overall beauty of these unique products.

Micro-printing

Aurum® feature anti-counterfeiting micro-printed designs embedded within the artwork that can be verified using a simple magnifying glass. This printing technique uses high quality imaging at a resolution that cannot be reproduced by common laser printers, scanners, or photocopiers and is the same technique commonly used in stock certificates and printed currencies.

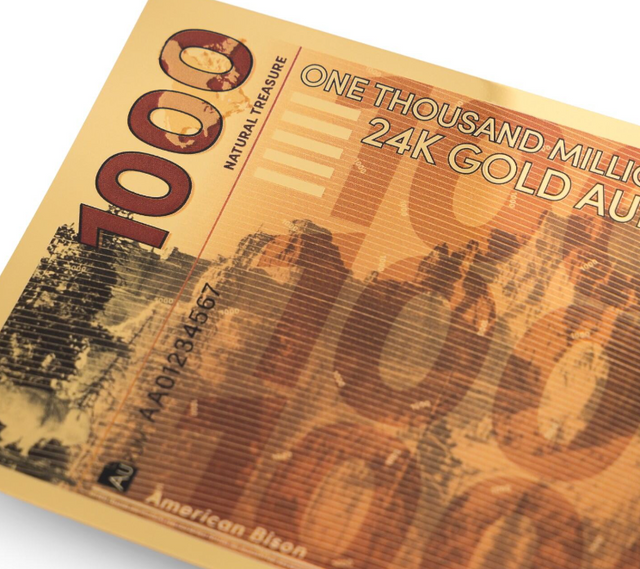

Reverse Side Dimensional Gold

Each Aurum® is made by precisely depositing gold, atom by atom, onto a printed polyester substrate. This process produces a unique effect on the reverse side. In unprinted areas the gold holds a high sheen. However, where gold atoms have fallen on the printed artwork the gold acquires a matte finish for a lightly embossed effect. This visual contrast can only be created using specialized deposition equipment and is a patented part of our production process.

Serial Numbers

Individual Aurum® are printed with a unique serial number that guarantees the authenticity of your piece. The placement of serial numbers varies within each design and is usually integrated into the overall artwork. To authenticate your Aurum, contact us to check the serial number and verify that it matches the issue information.

Authentication

Color and Transmission Spectrum

Gold has an iconic luster and rich color that makes it immediately identifiable. In fact, gold is only ‘gold’ colored when you look at its surface. When gold is manufactured thin enough that light passes through the layer, gold acquires a unique blue-green hue. The distinct blue-green color of ultra thin gold can also be used to precisely measure the presence and amount of gold. Valaurum uses a spectrometer during the manufacturing process to test and measure the spectrum of the transmitted light at both visible and invisible wavelengths within each issue.

Electrical Resistance

Gold has very low electrical resistance, which means electricity can flow through it with relative ease. The thickness of gold also determines how much electricity can flow. Thicker amounts of gold allow more free flow of electricity for a given voltage in the same way that a larger pipe allows more water to flow at a given pressure. Valaurum verifies the amount of gold by testing and measuring the precise electrical resistance in each issue of Aurum®.

Serial Number

Authentic Aurum® have unique serial numbers that can be verified. To authenticate your Aurum®, contact us to check the serial number and verify that it matches the issue information.

Designing the Aurum®

High Quality Artwork

Aurum® are designed using high resolution, full color artwork elevated by the premium sheen of gold visible throughout each piece. A combination of proprietary printing techniques, the unique interplay of gold and ink create a unique product unlike anything else available on the market today.

Secure by Design

Aurum® are printed with anti-counterfeiting micro-printed designs embedded within the artwork and can be verified by anyone using a simple magnifying glass. This printing technique uses high quality imaging at a resolution that cannot be reproduced by common laser printers, scanners, or photocopiers, the same technique commonly used within stock certificates and printed currencies.

Dimensional Gold

Each Aurum® is made by precisely depositing gold, atom by atom, onto a printed polyester substrate. This process produces a unique effect on the reverse side of the Aurum®. Unprinted areas within each design leave the gold with a pure, mirror-like sheen, similar to proof-like coins. However, where gold atoms have fallen on the printed artwork, the gold acquires a matte finish for a lightly embossed effect. This visual contrast can only be created using specialized deposition equipment and is a unique aspect of our production process that is patented by Valaurum, Inc.

Manufacturing Aurum®

Bringing Gold Into The Modern Age

Setting a New Standard

The Aurum® represents an unprecedented improvement compared to typical techniques currently available on the market. Traditional methods involve gold foil, which is is hand beaten or machine milled to achieve a specific thickness. As foils are milled more thinly, the cost increases, meaning that it is more expensive and more to deliver smaller increments of gold. Current foil manufacturing processes lack consistency, and the metals are typically unrecoverable. Furthermore, foil products do not include the Aurum’s cutting edge security features.

Precision at Every Step

Valaurum’s processes guarantee maximum control and precise application of gold in each issue. The uniform application of gold requires remarkably precise nanotechnology. In many Aurum®, the gold is actually applied atom-by-atom, as a three-dimensional structure. The surrounding polyester substrate protects the gold and carries further authentication features. The result is gold in a format that is both highly durable and secure.

Edge-to-Edge 24k Gold

The Aurum® is manufactured with a thin film deposition method similar to the processes used to manufacture semiconductors. During this process, a large gold plate is bombarded with high energy ions in a sealed vacuum chamber. The precious metal is vaporized into a spray that condenses and attaches to a polymer substrate. This micro layer of gold is highly precise, making it possible for Valaurum to manufacture a variety of denominations comparable to common paper currencies.

Gold Recovery

The gold from an Aurum® is easily recovered using standard fire assay techniques. Fire assay is an inexpensive, routine procedure commonly used by jewelers and metal refiners.

In a fire assay, the Aurum® is cut into strips and rolled into a cylinder before being placed in a ceramic crucible. The material is heated until the protective coating is burned away. After cooling, the remaining material is heated again with borax and cooled a second time. Lastly, the resulting glass is broken open, leaving behind a precise amount of gold.

We recommend seeking the assistance of Valaurum or other industry professionals to recover your gold. Fire assay should never be attempted by inexperienced metal workers or without the correct tools.